Our Contributions To The DECOAT Project

DECOAT was a collaborative project with 16 other partners from across Europe, aiming to tackle the challenging recycling of coated textile and plastic materials.

The main goal of DECOAT was to enable circular use of textiles and plastic parts with multilayer ‘coatings’, which are typically not recyclable yet. These ‘coatings’ comprise of functional and performance coatings and paints as well as adhesion layers. In the projects novel triggerable smart polymer material systems and the corresponding recycling processes were targeted. The triggerable solutions were based on smart additives (like microcapsules or microwave triggered additives) for ‘coating’ formulations that can be activated by a specific trigger (heat, humidity, microwave, chemical).

Our main involvement in the DECOAT project was to design, build and demonstrate instrumented laboratory systems for treating samples using microwave fields.

The Microwave Test System

For the first part of the project, we designed, built, commissioned, and implemented a test system capable of measuring the heating response of coated hard plastic and fabric samples upon treatment with microwave energy.

Design And Build:

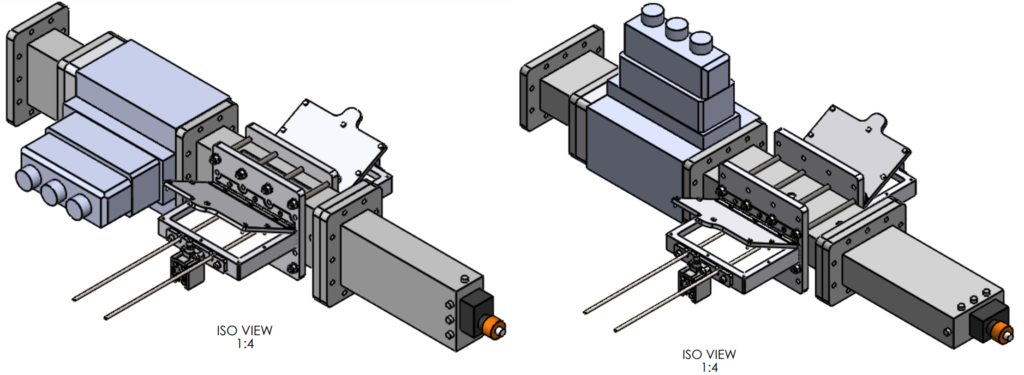

A key feature of this system was the capability to test samples in either parallel or perpendicular positions, achieved using two interchangeable waveguides in contrasting orientations. In either operation mode, temperature sensing was used to monitor the live temperature response upon application of microwave energy.

Assembly images to show the C-Tech Innovation microwave test system perpendicular (left) or parallel (right) orientations.

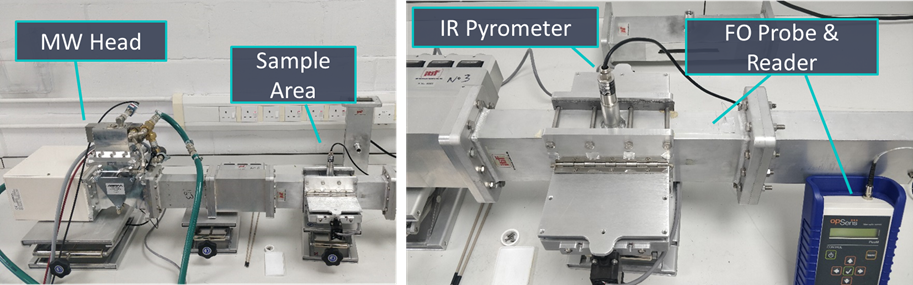

Photographs of the C-Tech Innovation microwave test system (left) with a close up of sample area of the test system (right).

Laboratory Trials

We investigated the effective dielectric properties of additive candidates by measuring the thermal response upon application of a microwave field. During this work, coatings on fabric and hard plastic materials were activated – successfully demonstrating microwave energy can be used to heat samples to the target temperature.

The Microwave Pilot Scale System

For the second part of the project, we designed, built, commissioned, and implemented a bespoke pilot scale system which uses microwave heating to trigger delamination of the coating from the polymer substrate.

Design and Build:

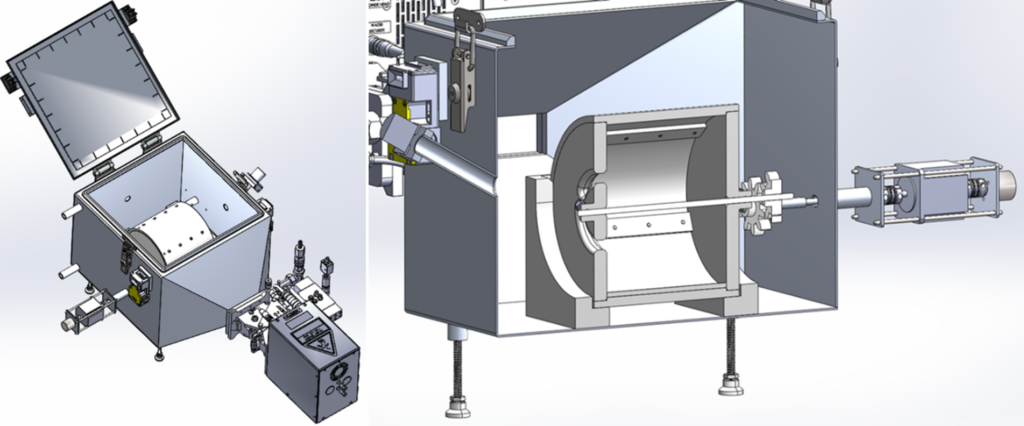

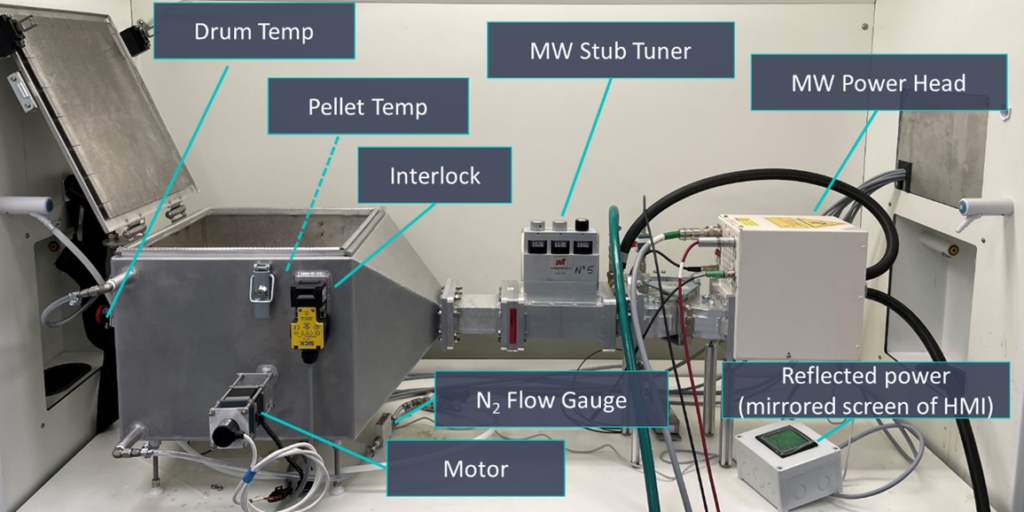

The microwave system was designed to be a larger scale version of the test equipment, with the purpose of processing batches with a maximum theoretical throughput of 30 kg·hr-1. The system had a rotating PTFE drum to provide mixing during sample processing within the microwave cavity. Live monitoring of the sample processing was achieved through sample temperature measurements by a non-contact infrared temperature sensor through a window in the drum.

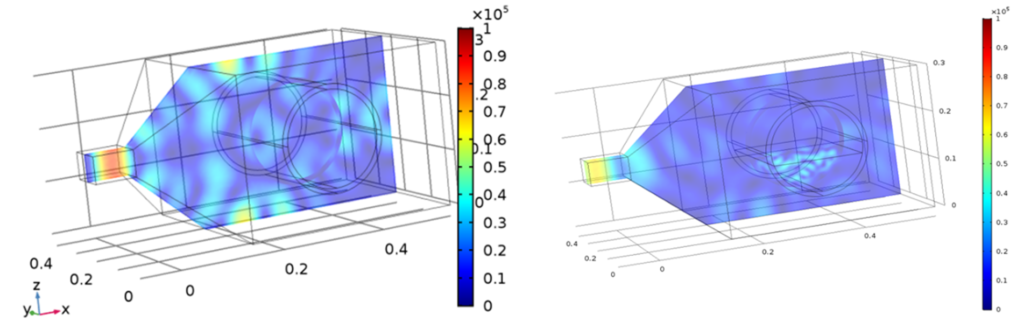

The design of the components and controls was critical to ensure safe and effective delivery of the microwave energy to the sample load. The system was controlled via an HMI, with programmable parameters including motor speed, microwave power and microwave pulse duration. Safety features were integrated into the setup including interlocks, containment of the microwave field and monitoring with leakage surveys, purge gas duration, low flow alarms, high temperature trip limits and temperature monitoring of the drum in case of thermal runaway. The apparatus was fitted with a stub tuner to minimise reflected microwave power, maximising the density of the electric field at the sample. The design was validated by computational modelling, which indicated the electric field became concentrated at the load upon addition of a susceptible material into the drum.

General assembly of the microwave pilot scale system (30 kg·hr-1), showing the whole apparatus (left) and the cavity fitted with the drum (right).

Modelling images to show the electric field distribution within the cavity with an empty drum (left) and with a loaded drum (right).

Photograph of C-Tech Innovation microwave pilot scale system.( 30 kg·hr-1)

Laboratory Trials:

Coated substrates were treated using the C-Tech Innovation microwave pilot scale system with live monitoring of the processing by temperature measurements. Microwave treated samples were similar to thermally treated samples, consistent with microwave energy delivering a thermal trigger. Processed areas of coatings could be removed upon manual separation – successfully demonstrating microwave energy can be used to heat substrates and trigger delamination.

Project Conclusions:

The work conducted at C-Tech Innovation showed that microwave energy can be used to heat coatings with susceptible additives past their thermal trigger temperatures, inducing delamination. This finding successfully demonstrated the concept of this technology.

You can read more about the project here: https://decoat.eu/

This article was written by our Process Development Team Leader Matt Sinclair